- Home Page

- Company Profile

-

Our Products

- Hydraulic Cylinders

- Hydraulic Jacks

- Hydraulic Powerpack

- Hydraulic Pumps

- Hydraulic Manifold

- Hydraulic Pallet Truck

- Oil & Diesel Loading & Unloading Transforming Pump

- Hydraulic Accessories

- Pressure Gauges

- Temperature Gauges

- Pressure Transmitter

- Digital Temperature Display

- Solenoid Valves

- Pneumatic automated valves

- Butterfly valves

- Ball Valves

- Pneumatic cylinder Valves

- Hydraulic hoses

- SS Hoses

- Hydraulic Stackers

- Hydraulic Lifts

- Hydraulic Press Machine

- Special Type Manifold Block

- Power Press

- Extra Link

- Contact Us

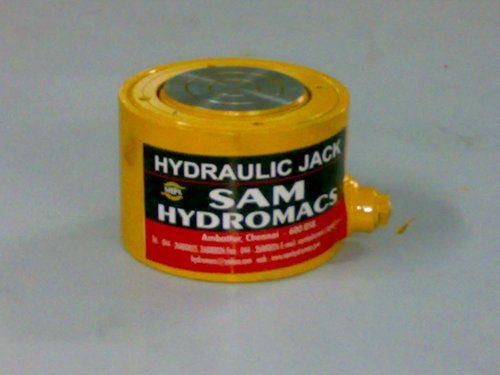

Industrial Hydraulics Jacks

Product Details:

- Usage Industrial

- Body Material Stainless Steel

- Size Yellow

- Structure Standard

- Color Silver

- Warranty Yes

- Click to view more

X

Industrial Hydraulics Jacks Price And Quantity

- 10 Unit

Industrial Hydraulics Jacks Product Specifications

- Yellow

- Yes

- Standard

- Silver

- Stainless Steel

- Industrial

Industrial Hydraulics Jacks Trade Information

- Cash in Advance (CID)

- 30 Unit Per Month

- 2-7 Days

- All India

Product Description

After analyzing the specific needs of this industry, our company is manufacturing and exporting a wide range of Industrial Hydraulics Jacks. We do not compromise with the quality of offered hydraulic jacks, hence we source high-end quality materials from reliable vendor base for manufacturing these as per industrial standards. Suitable for power and handling operations, these hydraulics jacks are popular in the market for their fine finish, sturdy structure and excellent durability. Clients can avail Industrial Hydraulics Jacks from us at economical prices.

Types of Jacks

- Bottle Type

- Remote Type

- Customized Jacks

- 2 tonnes and up to 500 tones capacity

| Performance Specifications

Jack Type

Actuation

Features

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Superior Build for Demanding Environments

Constructed from high-quality stainless steel, our hydraulic jacks are engineered to withstand extreme working conditions and repeated use. The material ensures resistance to rust and deformation, making them reliable for industries where strength and longevity matter most. The standard structure allows seamless integration into existing systems.

Efficient and Safe Lifting Solutions

Our hydraulic jacks utilize advanced hydraulic mechanisms, which translate to safe, efficient, and controlled lifting. The yellow size and silver color enhance visibility in busy workspaces, reducing hazards. With a manufacturers warranty, you can trust in both performance and long-term safety.

FAQs of Industrial Hydraulics Jacks:

Q: How do I operate the Industrial Hydraulic Jack safely?

A: To operate, position the hydraulic jack on a firm, level surface beneath the designated lifting point. Use the handle to pump and activate the hydraulic mechanism, raising the load gradually. Always follow the manufacturers operational guidelines and ensure proper placement to maximize safety.Q: What are the primary benefits of using a stainless steel hydraulic jack in industrial applications?

A: Stainless steel construction offers excellent resistance to corrosion and mechanical wear, ensuring longevity and reliability. This material also enhances the jacks strength, making it suitable for heavy industrial use, even in harsh or humid environments.Q: When should I choose a standard-structured hydraulic jack over specialized models?

A: A standard-structured hydraulic jack is ideal for most general lifting tasks in industrial environments where versatility and compatibility are required. Choose this option when you need a jack that integrates easily across various projects or machinery without the need for custom modifications.Q: Where is this hydraulic jack manufactured and how does it impact quality?

A: These hydraulic jacks are manufactured and supplied in India by reliable industry experts. Rigorous quality control ensures that each unit meets stringent standards, offering consistent performance and robust build quality.Q: What is the process for requesting warranty service on this product?

A: If you experience any issues within the warranty period, contact the manufacturer or supplier with your purchase details. They will guide you through the process, which may include inspection, repair, or replacement in accordance with warranty terms.Q: How can this hydraulic jack be used in an industrial setting?

A: These jacks are perfect for lifting heavy machinery, positioning equipment, or supporting structures during maintenance. Their robust build and hydraulic mechanism ensure efficient lifting with minimal manual effort, streamlining many industrial operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Jacks' category

|

SAM HYDROMACS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS