- Home Page

- Company Profile

-

Our Products

- Hydraulic Cylinders

- Hydraulic Jacks

- Hydraulic Powerpack

- Hydraulic Pumps

- Hydraulic Manifold

- Hydraulic Pallet Truck

- Oil & Diesel Loading & Unloading Transforming Pump

- Hydraulic Accessories

- Pressure Gauges

- Temperature Gauges

- Pressure Transmitter

- Digital Temperature Display

- Solenoid Valves

- Pneumatic automated valves

- Butterfly valves

- Ball Valves

- Pneumatic cylinder Valves

- Hydraulic hoses

- SS Hoses

- Hydraulic Stackers

- Hydraulic Lifts

- Hydraulic Press Machine

- Special Type Manifold Block

- Power Press

- Extra Link

- Contact Us

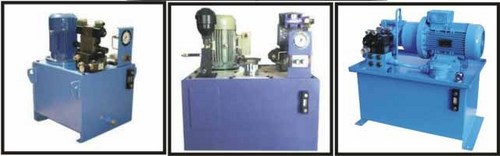

Hydraulic Custom Made Powerpack

15000.00 - 150000.00 INR/Piece

Product Details:

- Sealing Type Nitrile / Viton / Polyurethane (as per specification)

- Accessories Oil Cooler, Accumulator, Temperature Switch, Level Sensors, Filters, Valves

- Flow Rate Up to 100 LPM (customizable)

- Features Low Noise, Oil Level Indicator, Pressure Gauge, Emergency Stop, Overload Protection

- Power Source Electric Motor

- Operating Pressure Up to 350 Bar

- Mounting Type Base Plate Mounted / Custom Mounting

- Click to view more

X

Hydraulic Custom Made Powerpack Price And Quantity

- 15000.00 - 150000.00 INR/Piece

- 1 , , Piece

Hydraulic Custom Made Powerpack Product Specifications

- Custom Made Powerpack

- Mild Steel / Stainless Steel (as per customer requirement)

- Compact, Modular, Welded Frame

- Adjustable, Up to 2500 RPM

- 230V / 415V AC, 50 Hz (customizable)

- Oil Cooler, Accumulator, Temperature Switch, Level Sensors, Filters, Valves

- Nitrile / Viton / Polyurethane (as per specification)

- Low Noise, Oil Level Indicator, Pressure Gauge, Emergency Stop, Overload Protection

- Up to 100 LPM (customizable)

- High Efficiency, Energy Saving

- Industrial Automation, Machine Tools, Presses, Lifts, Construction Equipment

- Up to 300 Tons (customizable)

- Electric Motor

- Base Plate Mounted / Custom Mounting

- Up to 350 Bar

Hydraulic Custom Made Powerpack Trade Information

- 20 , , Piece Per Day

- 5-7 Days

Product Description

Owing to the support of our dedicated professionals, we are cable to manufacture and export a wide range of Hydraulic Custom Made Powerpack. These powerpacks are manufactured by us as per industrial standards using supreme quality materials and components. Ideal for heavy duty material handling equipments, these powerpacks are broadly used for filter and hydraulic presses. Our Hydraulic Custom Made Powerpack is easy to use and appreciated among our clients for its durability and unmatched performance.

Design

- Steel tank 16, 30, 55, 75, 100 & 180 litre

- Aluminium Gear Pumps

- Pressure up to 400 bar

- Flow rates to 100 litres / minute

- Suction filter 90 micron

- Return filter 25 micron

- Submerged Pump

- Cetop subplate options

- 1 phase to 3 kw

- 3 phase to 30 kw

Quality

- 100% functional testing

- Tanks with painted finish

- Motors IEC frame B5 IP55

- Supplied with C TO C

We are exceptional producers of Hydraulic Cylinders in the following criterion:- Standard and non standard

- Welded and Tie rod construction

- Single / Double acting

- Bore dia 25 to 600 mm

- Stroke upto 5000mm

- Max working pressure 400 kg/cm2

- Varies type of mountings

- Friction free imported sealkits Bushak Shampon, Parker, Hellite, Merkkal

- Boring and Honning in house facility

Types of Mounting includes:

- Front Flange

- Rear Flange

- Rod Side and Rear Side Clevis

- Both side Clevis

- Trunion Mounting

- Leg Mounting,etc.,

| |

Tailored Hydraulic Solutions for Every Industry

Whether you operate in industrial automation, presses, lifts, or construction equipment, our hydraulic powerpacks are customized to fit your exact requirements. Choose from multiple materials and mounting styles to match your operating environment. Optional accessories like oil coolers, accumulators, sensors, and filters further enhance system capability and reliability. Our engineering team ensures seamless integration into your workflow, maximizing both efficiency and safety on the job.

Superior Performance and Energy Efficiency

Achieve robust hydraulic performance with powerpacks capable of handling up to 300 tons of force, variable speeds, and high-efficiency energy usage. Advanced featuresincluding low noise operation, oil level indicators, and overload protectioncontribute to reduced operational costs and a safer work environment. Precision manufacturing and modular design make maintenance straightforward, ensuring dependable operation for years to come.

FAQs of Hydraulic Custom Made Powerpack:

Q: How can I customize a hydraulic powerpack to fit my specific application?

A: You can specify your required frame material (mild steel or stainless steel), force capacity, speed, voltage, operating pressure, flow rate, sealing type, and mounting style. Our engineers will work closely with you to design a powerpack that seamlessly integrates with your machinery or process requirements.Q: What is the typical process for ordering a custom-made hydraulic powerpack?

A: The process begins with a detailed consultation to understand your technical needs and application. Based on your inputs, we design a personalized solution and provide a quotation. Upon approval, manufacturing commences, followed by rigorous testing and on-time delivery from our facility in India.Q: Where can these hydraulic powerpacks be used effectively?

A: These custom hydraulic powerpacks are ideal for industrial automation systems, machine tools, presses, lifts, construction machinery, and more. Their modular design and flexibility make them suitable for a wide range of operational environments that demand high efficiency and reliability.Q: What benefits do these powerpacks offer in terms of efficiency and safety?

A: Our hydraulic powerpacks feature energy-saving operation, high efficiency, and integrated safety mechanisms such as emergency stop, overload protection, oil level indicators, and pressure gauges. This combination ensures stable performance, reduced downtime, and greater control over the hydraulic system.Q: How does adjusting the speed and flow rate enhance equipment performance?

A: Adjustable speed up to 2500 RPM and customizable flow rates (up to 100 LPM) allow you to fine-tune the hydraulic output to match the demands of your application, optimizing productivity while minimizing energy consumption and component wear.Q: When should accessories like oil coolers or accumulators be included?

A: Accessories such as oil coolers and accumulators should be selected based on the operational intensity, duty cycle, and environmental factors. Including these ensures stable temperatures, pressure balancing, and extended system lifespan, especially in demanding or continuous use scenarios.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Powerpack' category

|

SAM HYDROMACS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS